Table of Contents

ToggleEverything You Must Understand About Wick Desoldering

The ability to successfully solder and desolder components is one of the most important abilities when working with electronics. The process of desoldering is essential whether you’re fixing a circuit board, altering an existing gadget, or developing a new project. Of the many solder removal methods available, the desoldering wick, sometimes referred to as solder braid, is a popular choice for both hobbyists and experts. The definition of a desoldering wick, its benefits, how to use it, and best practices will all be covered in this blog.

A desoldering wick: what is it?

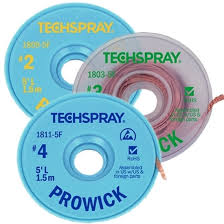

A desoldering wick is a copper braid used to remove undesired solder from circuit boards and electrical components. The wick, which is usually composed of thin, woven copper wires, is covered with flux to improve its solder-absorbing capacity. It may be used for a variety of desoldering tasks because it comes in a range of widths and lengths.

Capillary action is the mechanism via which the wick functions. Molten solder is drawn away from the connection by the copper braid when heated with a soldering iron, leaving the area clean and prepared for rework or repair.

A Desoldering Wick: Why Use It?

There are numerous reasons why the desoldering wick is a popular option.

Precision: It is perfect for fragile components and closely spaced circuit boards because it enables the precise removal of solder.

Cleanliness: By absorbing the majority of the solder residue, a desoldering wick leaves the region cleaner than alternative techniques, including employing a solder sucker.

Easy to operate: Anyone can learn how to operate a desoldering wick efficiently with little instruction.

Affordability: Due to its low cost, both novices and experts can utilize this instrument.

How a Desoldering Wick Is Used

Although using a desoldering wick is simple, getting the best results requires careful attention to detail. Here is a detailed guide:

Get Your Equipment Ready: Assemble the required supplies, such as:

Wick desoldering

If the wick isn’t already fluxed, soldering iron flux

A set of scissors or tweezers

Safety gear, such as gloves and goggles

Turn the soldering iron on: Make sure your soldering iron is heated to the proper temperature. A temperature of 350°C to 400°C (662°F to 752°F) is ideal for the majority of solder types. To prevent harming parts or the circuit board, make necessary adjustments.

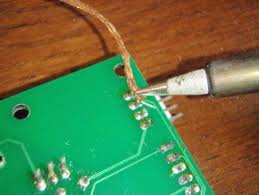

Position the Wick: Cover the solder junction you wish to remove with the desoldering wick’s end. For effective solder absorption, make sure the wick covers the entire surface.

Apply Heat: Lightly touch the wick with the heated soldering iron tip. The solder will melt as the heat moves through the copper braid and be pulled into the wick.

Eliminate the Wick: Lift the wick and soldering iron away at the same time after the solder has been absorbed. Because too much heat can harm the circuit, take care not to leave the iron on the board for an extended period of time.

Trim the Used Wick: Use wire cutters or scissors to snip off the solder-containing section of the wick. This guarantees that the following joint will always have a new, unused area.

Examine and repeat as needed: Verify that all of the solder has been removed by inspecting the region. Repeat the procedure with a fresh slice if residue is still present.

Advice for Successful Desoldering

Make Use of the Proper Width Select a wick width that is suitable for the task. Large joints benefit from a bigger wick, whereas precision work requires a tighter wick.

Keep the Wick Fresh: To optimize solder absorption, always utilize a clean portion of the wick. Efficiency is decreased when a used section is reused.

Add Flux if Needed: To enhance wick performance, apply a tiny bit of flux if your wick isn’t already fluxed or if you’re dealing with solder that won’t go away.

Steer clear of overheating: Extended heat can harm parts and raise PCB traces. Apply heat for no more than a few seconds at a time.

Work in an Area with Good Ventilation: Inhaling flux and solder vapors can be dangerous. Use a fume extractor or make sure there is enough ventilation.

Benefits of Desoldering Wick Use

When compared to alternative techniques, the desoldering wick offers the following advantages:

Environmentally Friendly: The wick absorbs everything, minimizing waste, in contrast to a solder sucker that could leave small pieces of solder behind.

Accessibility in Tight Spaces: Because of its thin profile, it can get to places that a solder sucker or other equipment might find difficult to reach.

Dependability for Fine Work: Compared to other tools, the wick is less likely to harm components when working on delicate electronics like microcontrollers or heavily populated PCBs.

Limitations to Take Into Account

Despite its great effectiveness, the desoldering wick has many disadvantages.

Limited Reuse: Because a wick may only be used once per piece, it is not as economical for large-scale projects.

Slower Process: For large amounts of solder, the desoldering wick may take longer than a solder sucker.

Needs a Learning Curve: Without practice, beginners may find it difficult to strike a balance between solder absorption and heat application.

Typical Uses

The desoldering wick is useful in a number of situations:

Repairing electronics involves removing malfunctioning parts or scraping away extra solder.

Resolving soldering errors during prototype assembly is known as prototyping.

Making adjustments to current circuit designs without causing harm to components is known as rework and modification.

In conclusion

Anybody who works with electronics has to have a desoldering wick. It is a mainstay in repair and prototyping work due to its accuracy, cost, and simplicity of usage. You’ll be prepared to tackle even the most difficult desoldering jobs if you can grasp the methods described in this tutorial and put the advice to use.

Investing in a high-quality desoldering wick will greatly improve your soldering and desoldering abilities, regardless of your level of experience. Therefore, use a desoldering wick the next time you encounter a challenging solder junction; it might just be the solution!